Polymers have replaced metals in many industries such as aerospace, military, packaging, etc. due to significant advantages such as greater strength and rigidity, lightness, and formability. These polymers include polyethylene, polypropylene, polyurethane, polyamides, polyether ether ketones, and polyvinyl chloride.

Polyvinyl chloride, abbreviated as PVC, is a thermoplastic polymer that is widely known in the world. This polymer is produced annually in the world at about 45 million tons and is the third most widely used polymer in the world after PE and PP. PVC has a longer history than most plastics. It was first synthesized in 1872 and manufactured in 1920 by the B.F. Goodrich Company of the United States and became commercialized in the 1940s and 1950s.

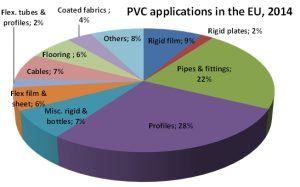

The figure below shows the use of polyvinyl chloride in various industries:

The softening point of thermoplastic polyvinyl chloride is approximately 80°C. It is lightweight, flame-retardant, strong and durable, has low gas permeability and good aeration, and its physical properties make it ideal for many different applications. It is also used in water pipes due to its good resistance to moisture absorption. This widely used polymer is classified as a thermoplastic or thermoplastic polymer. Thermoplastic polymers are materials that can be heated, cooled and shaped to their melting point and can be remelted and reshaped.

Polyvinyl chloride is produced in three forms: rigid (UPVC), flexible (PVC) and shaped polyvinyl chloride (OPVC). Flexible PVC is softer and more flexible than UPVC due to the addition of plasticizers such as phthalates (DOP). Flexible PVC is commonly used in construction as insulation in electrical wires or on floors in homes, hospitals, schools and other areas where a sterile environment is a priority and in some cases as a replacement for rubber. Unlike soft PVC, rigid PVC is very hard and inflexible due to the lack of plasticizers. Therefore, compared to other plastics, it is a suitable alternative for many industrial applications such as pipes, fittings and door and window profiles for construction.

Another form of polyvinyl chloride is OPVC or oriented PVC, which exhibits much higher physical and mechanical properties compared to UPVC and PVC due to the arrangement of the polymer chains in the appropriate direction. Therefore, with this structure, it is possible to produce lighter products with higher quality. An important point about OPVCs is the mechanism of increasing properties. PVC is essentially an amorphous polymer in which the polymer chains are arranged randomly. These chains exist under certain conditions of pressure, temperature and shear forces. This arrangement in both the axial and ring directions increases the mechanical properties such as impact strength; in such a way that the fragility mechanism of OPVC pipes eliminates the peeling condition present in UPVC pipes.