Industrial packaging production in Thunder North

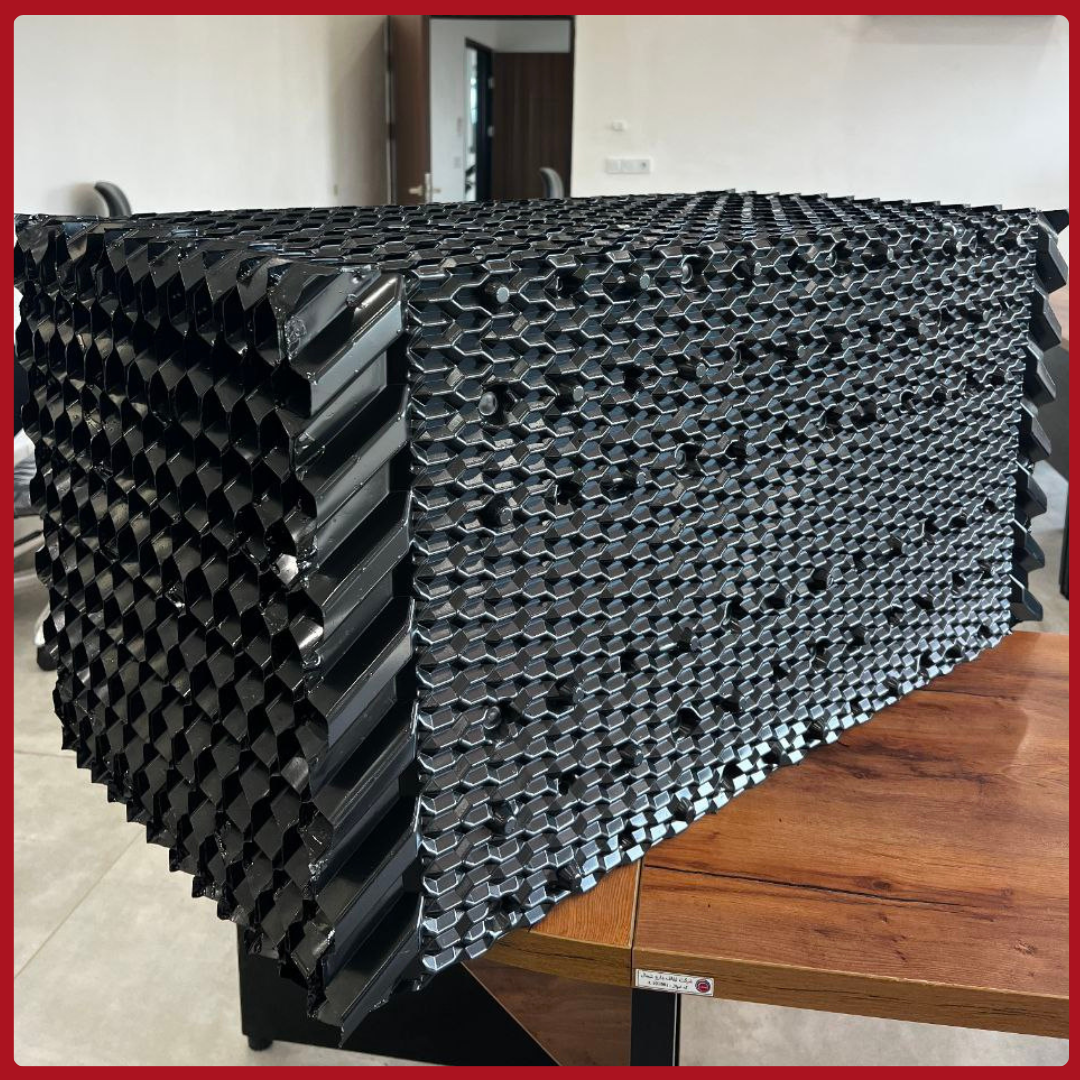

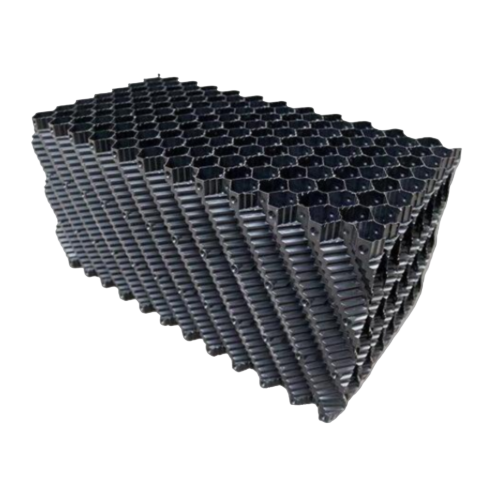

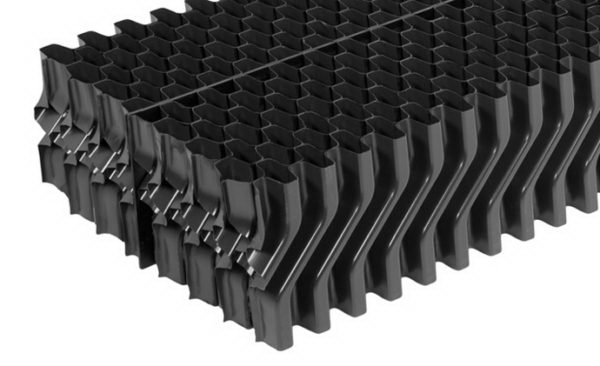

Thunder North is a specialized manufacturer of various types of industrial packings in standard pitches of 12, 14, 16 and 19 mm, as well as:

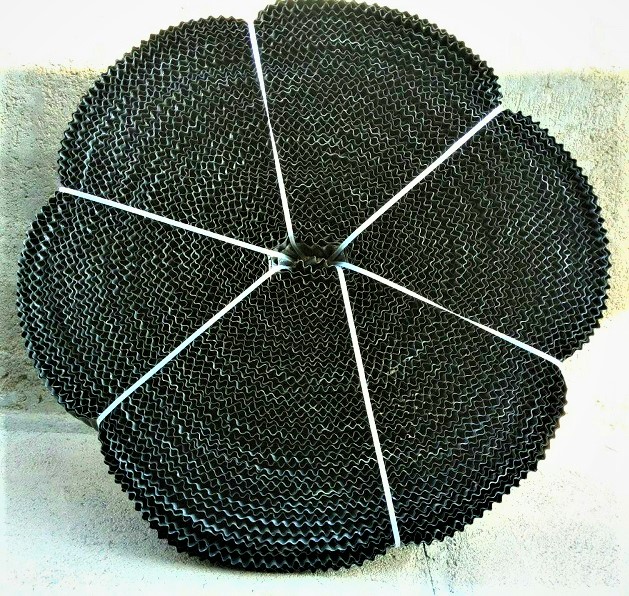

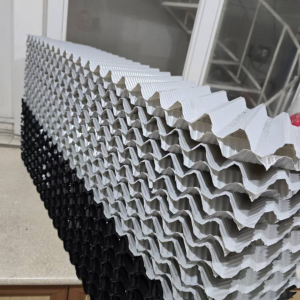

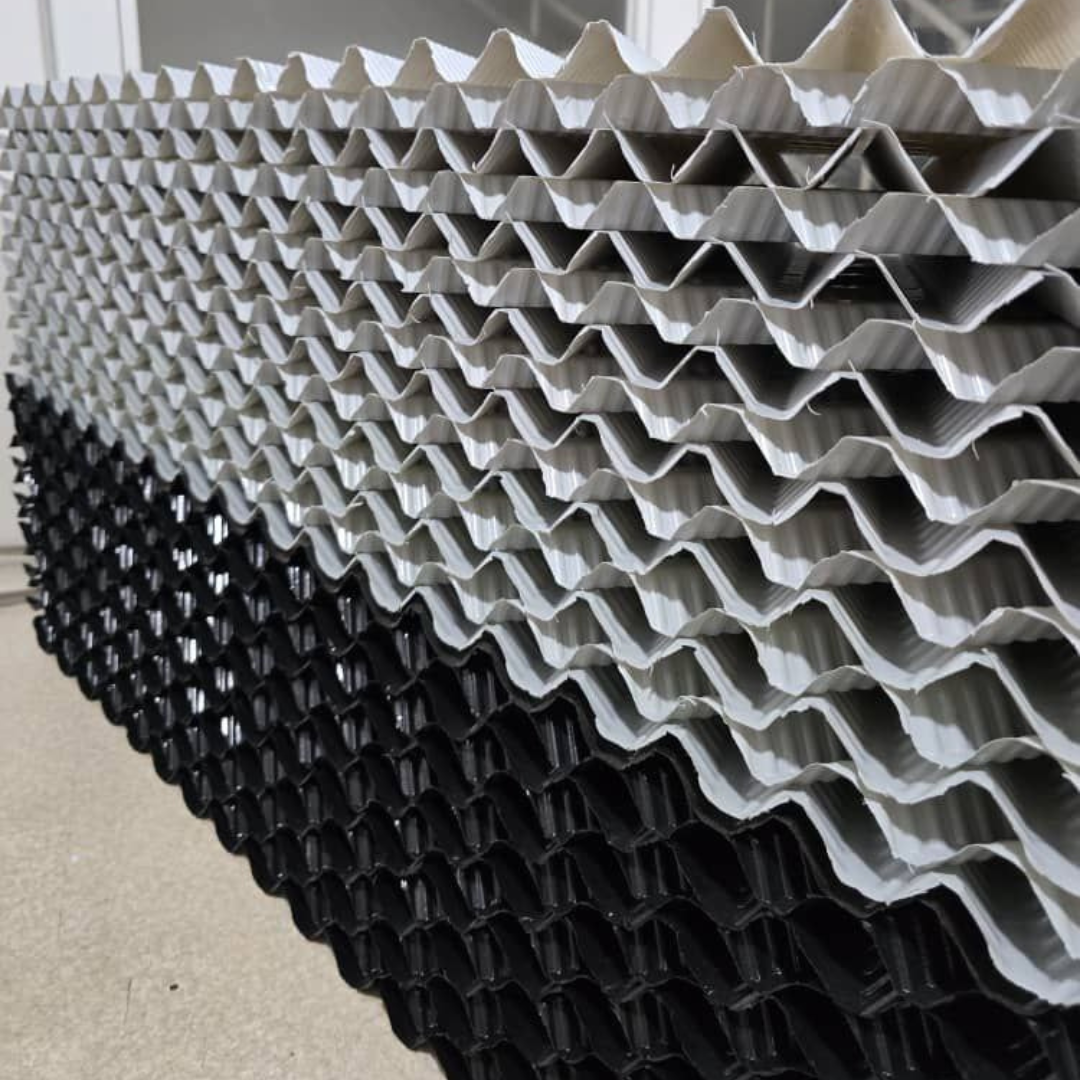

- Honeycomb drip catcher

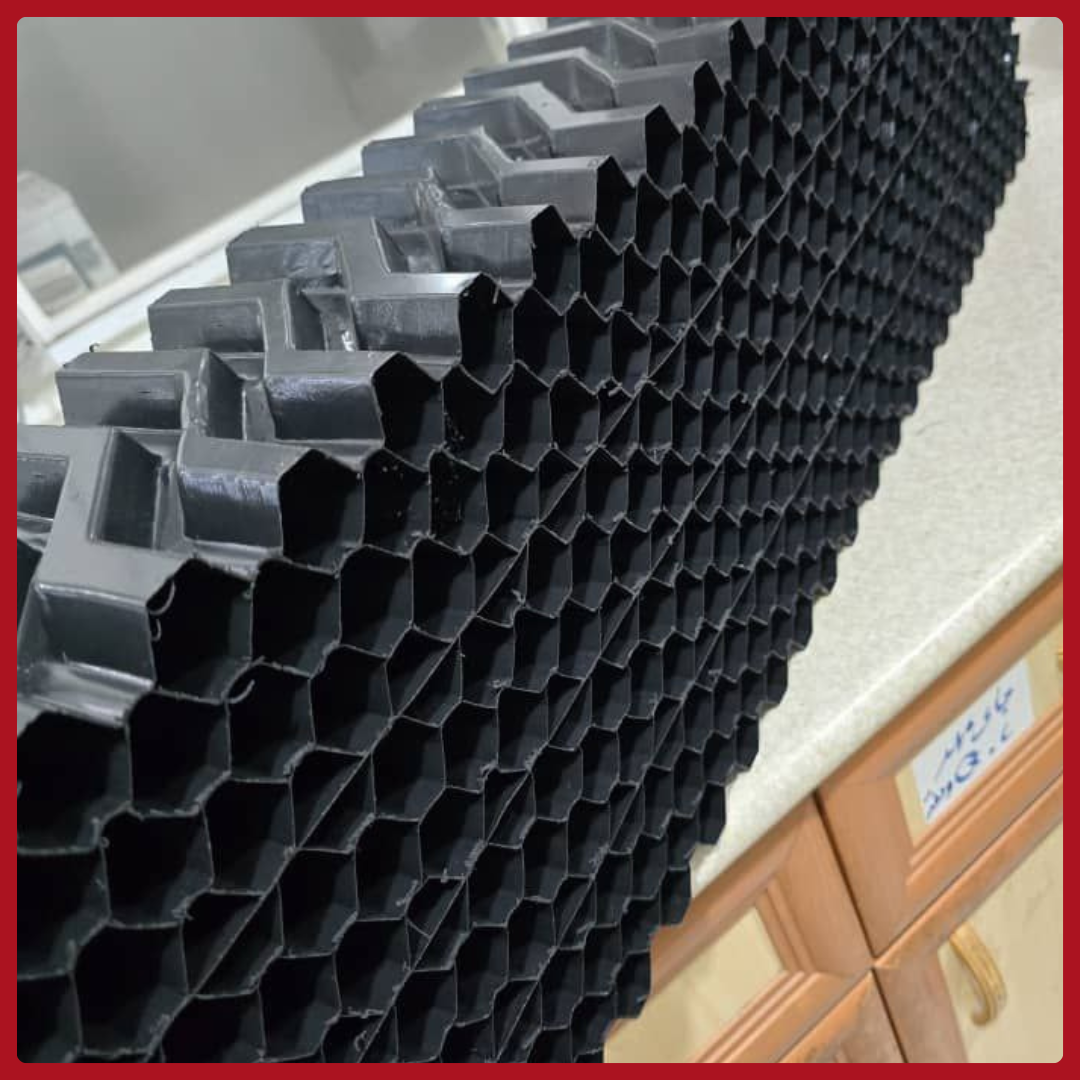

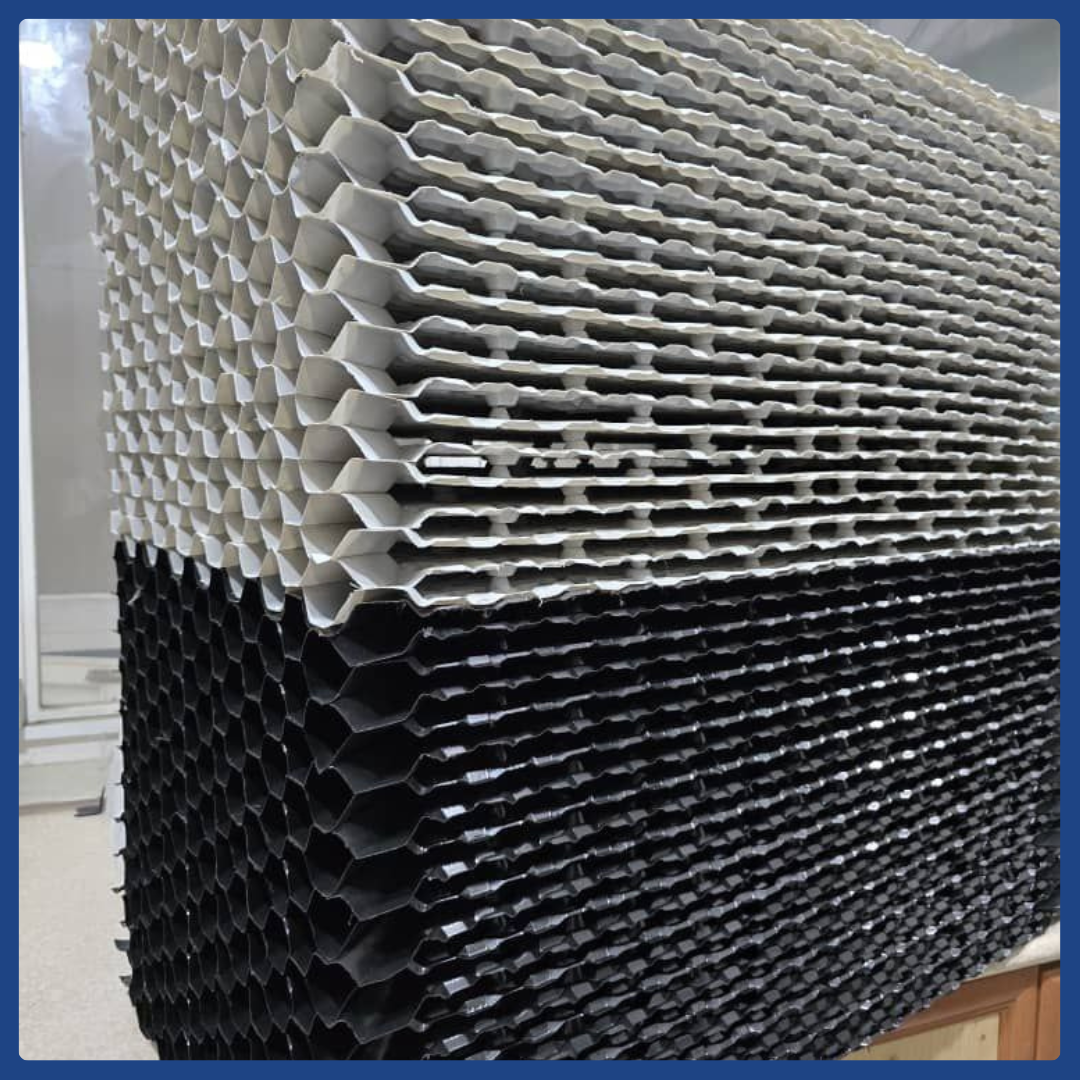

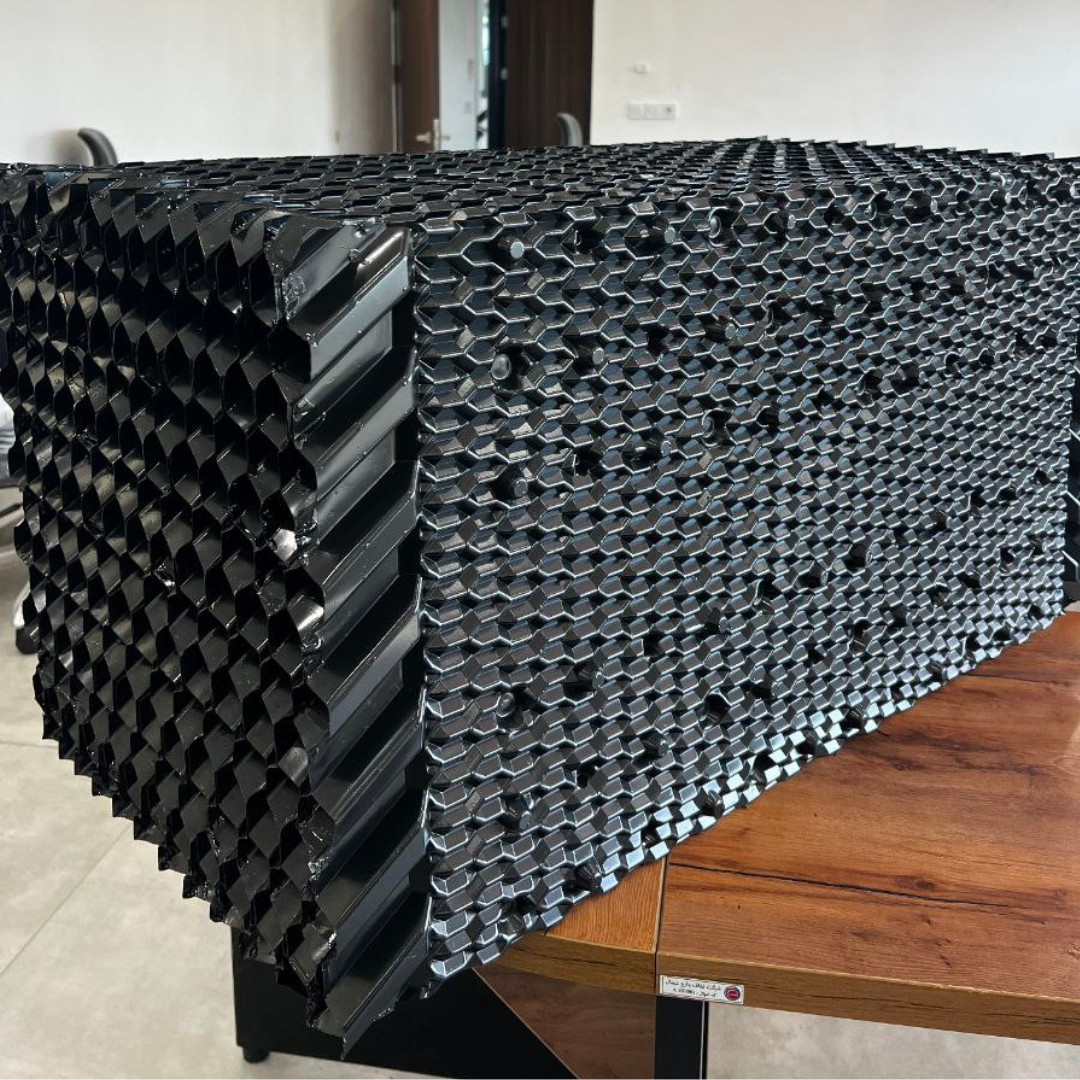

- Egg comb packing with drip stopper

We also have the ability to produce custom-made packing based on the needs of industrial projects.

Applications

Industrial cooling towers and air conditioning

Water and wastewater treatment plants

Aquaculture systems and circulating water ponds

Large industries: power plants, refineries, steel, petrochemicals

Products of Thunder North Vacuum Forming Site

Comparison table of types of packaging produced

| Packing type | Structure and pace | Main application | Benefits | Suitable for water quality |

|---|---|---|---|---|

| Packing pitch 12 mm | Film - compressed | Suitable for cooling towers with closed or semi-closed systems and low hardness water that require the highest heat exchange efficiency | High thermal efficiency, small space occupation, compact layout, light weight, resistance to brittleness against impact and cold, high thermal resistance against deformation, resistance to UV rays | Clean |

| Packing pitch 14 mm | Film - Medium | Application in industries with relatively good water quality that require a balance between thermal efficiency and resistance to fouling | Balance between efficiency and maintenance, easy installation, stable performance, resistance to brittleness against impact and cold, high thermal resistance against deformation, resistance to UV rays. | Fairly clean |

| Packing pitch 16 mm | A film - Opener | Suitable for systems with semi-polluted water; where there is a possibility of sediment and clogging in the system. | Reduced chance of clogging, long life, easier maintenance, resistance to brittleness against impact and cold, high thermal resistance against deformation, resistance to UV rays | Semi-polluted |

| Packing pitch 19 mm | Film - Large | Ideal for cooling towers with highly contaminated water or containing solid particles, in harsh industrial environments such as refineries. | Very high resistance to blockage, high durability, easy service and cleaning, resistance to brittleness against impact and cold, high thermal resistance against deformation, resistance to UV rays. | Infected |

| Egg comb packing with drip tray | Cellular structure + dripper | Used in situations where there is a need to maximize pressure drop reduction and minimize water droplet splashing; in confined spaces and light flows. | Increased contact surface, reduced water loss, improved thermal efficiency, resistance to brittleness against impact and cold, high thermal resistance against deformation, resistance to UV rays | Variable |

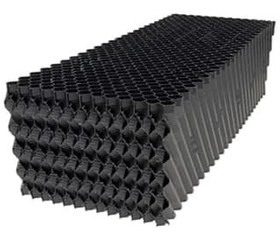

| Honeycomb drip catcher | Zigzag or crisscross | Installation at the top of the cooling tower to prevent water droplets from escaping into the environment and reduce waste. | Prevents moisture diffusion, saves water consumption, compatible with all types of packaging, brittleness resistance against impact and cold, high thermal resistance against deformation, resistance to UV rays | Variable |